Machine-Ready

TCI Precision Metals was built based on providing value to our customers by reducing or eliminating material prep, which significantly increases a shop’s throughput and efficiency. We talk a lot about Machine-Ready Blanks, which is at the core of what we do. Custom Machine-Ready Blanks are typically square, rectangular or round aluminum, stainless steel, or other alloy material pre-machined to close tolerances, eliminating the need for squaring and flattening later on. This allows customers to get right to the high-value work of finish machining. While this is a fairly straight-forward concept, there is much more beyond typical Machine-Ready Blanks.

It’s a Machine-Ready Blank Until It’s a Finished Part

At TCI Precision Metals, we are expert at efficiently removing large amounts of material, essentially the ‘heavy lifting’ of the machining process. The term “Machine-Ready Blank” applies to any value-added material that is not yet a finished part. In addition to typical Machine-Ready Blanks as described above, we also provide Machine-Ready Feature-added Blanks and Machine-Ready Roughing, often requiring grinding, milling and turning. In the end, the Machine-Ready Blanks delivered to the customer are either at or near finish net size, and depending on specifications still require high-value finish machining and possibly other processes before becoming a finished part.

At TCI Precision Metals, we are expert at efficiently removing large amounts of material, essentially the ‘heavy lifting’ of the machining process. The term “Machine-Ready Blank” applies to any value-added material that is not yet a finished part. In addition to typical Machine-Ready Blanks as described above, we also provide Machine-Ready Feature-added Blanks and Machine-Ready Roughing, often requiring grinding, milling and turning. In the end, the Machine-Ready Blanks delivered to the customer are either at or near finish net size, and depending on specifications still require high-value finish machining and possibly other processes before becoming a finished part.

The most significant customer benefit to being Machine-Ready is increased throughput on the shop floor. When you increase the rate of production through the shop by starting with a precision blank that is machine-ready, you ship out more parts in the same period of time, which increases profit and customer satisfaction.

TCI Machine-Ready Blanks are double disc ground and/or duplex milled so at least two sides of a part are cut at the same time. This translates into a cost savings over facing only one side of raw stock at a time. When the Machine-Ready Blanks arrive with additional features added, less in-house machine time is required.

Other ways of looking at increased throughput, include:

• Freeing time on the shop floor for better uses (ideally, more production)

• Reducing constraints that prevents the shipment of more product

• Identifying under-utilized capacity and putting it to better use

• Improving backlog by off-loading unnecessary prep work and second ops

• Increasing your shop’s capacity without adding unnecessary costs such as capex and payroll.

The following are examples of Machine-Ready applications provided by TCI Precision Metals:

Machine-Ready Blanks

Machine-Ready Blanks are square, rectangular or round aluminum, stainless steel, or other alloy blanks that are ground and/or milled to tight tolerances enabling a CNC machine to get right to final machining. This eliminates the need for squaring up the material prior to finishing the part.

Feature-Added Blanks

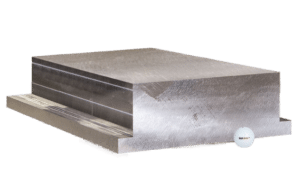

Feature-added Blanks are milled to the same tight tolerances as custom Blanks, but include one or more features specified by the customer. A typical added feature might be a large amount of material removal; for example, milling all six sides of a rectangular Machine-Ready Blank and adding opposing steps.

Machine-Ready Roughing

Machine-Ready Roughing delivers Blanks at near net size and shape, ready for finish machining. Roughing operations may include duplex milling, double-disc grinding, rotary ‘Blanchard’ surface grinding and CNC milling or turning. A typical added feature might be a large amount of material removal; for example, milling all six sides of a rectangular Machine-Ready Blank and then providing a sizable hole or pocket to reduce finish machine time on the customer’s floor. Machine-Ready Roughing is often used for castings to true up parts, add features or remove access material.

Starting a production job being Machine-Ready streamlines the pre-production stage, eliminates material bottlenecks and can dramatically speed up finish part production.

Thanks for reading.

John