A Reason to Celebrate

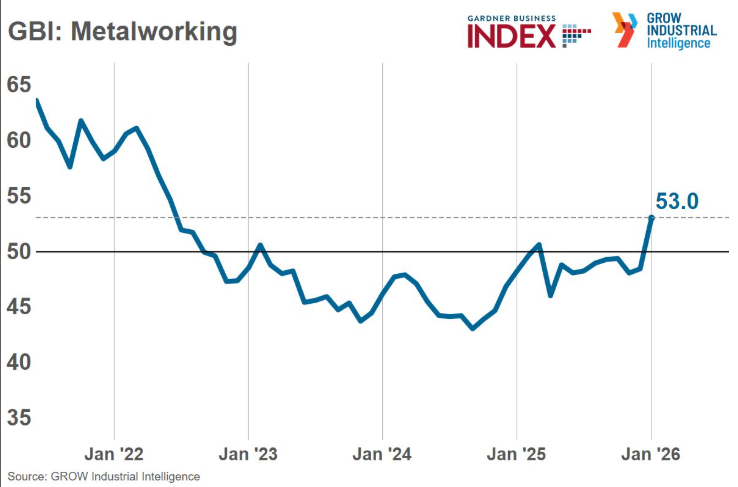

After more than 3-years of contraction and one of the longest slumps in the metalworking industry, things are looking up. Personally, I have felt the energy in the market building over the last few months, and now the January numbers are in and it’s official. The metalworking index is in growth mode at 53%. Now what?

As the market turns on and heats up the focus of many shops will soon turn from DIY to Get-it-Done. The goal being to get jobs out the door so you can bill it and get paid. Backlogs are not your friend. They may provide a false sense of security, but in the end, it is efficiency that wins the day.

Based on machine tool sales data it is evident that a lot of OEMs and tiered suppliers are still sitting on the sidelines waiting for market confidence to improve and stabilize further before investing in equipment. This same lack of confidence has driven many machine tool builders to reduce inventory exposure by cutting back on production. As demand increases, builders will find themselves in a backlog situation themselves with ever-increasing delays in delivery from months to more than a year. In the meantime, your customer wants their parts - now.

Now is the time for deliberate planning and a hard look at options that can materially increase efficiency and overall throughput. As demand returns, the challenge many shops will face is not a lack of work, but the ability to execute quickly, consistently, and profitably. The reality of doing more with less over the coming months and years is unavoidable, driven by skilled labor shortages, rising costs, and increasing customer expectations around lead times and quality.

For many manufacturers, this naturally leads to evaluating automation strategies. Five-axis machining solutions are often one of the first considerations, as they consolidate multiple operations into a single setup, reduce handling, improve part accuracy, and free up labor for higher-value tasks. In many cases, five-axis machining is not just a productivity upgrade, it is a practical form of automation that delivers immediate gains without the complexity of fully automated cells.

Beyond the machine tool itself, pallet pools, pallet changers, and robotic or cobot-assisted tending solutions can significantly extend spindle utilization, particularly during unattended or lights-out operation.

Another solution to consider is to evaluate and reassign existing machine assets. Capable machines are often underutilized, tied up in low-value or non-critical operations such as material prep simply because “that’s how it’s always been done.” Reassigning these machines to higher-value work, while offloading secondary processes, can unlock hidden capacity.

This is also an ideal moment to revisit value stream mapping with fresh eyes. As volumes increase, inefficiencies that were tolerable during slower periods quickly become bottlenecks. Material flow deserves particular attention. Material sourcing and preparation (sizing, squaring, flattening, deburring, and cleaning) can represent 50% or more of total job time and are frequently the root cause of production interruptions and extended cycle times. Addressing these upstream processes often delivers faster and more sustainable gains than focusing solely on cutting time at the machine.

At this point I should avoid a shameless plug for pre-machined materials, but they are proven to increase machining throughput on production jobs by 25% or more.

Taking the time to plan now, before backlogs swell and delivery windows tighten, will put you in control of the next growth cycle rather than reacting to it. The winners in the next phase of the market will not be those who simply add work, but those who execute smarter, faster, and with greater consistency.

I am happy and relieved for your business, our business, and the metalworking industry at large. It’s been a long dry spell, but the market seems to be getting sustained lift and for this I am grateful.

Good luck - let’s get to work!

Thanks for reading -

Ben