- Home

- Browse Catalog and Order Now

- Ready to Ship Blanks

- Made to Order Blanks

- Aluminum & Steel Custom Vice Jaws

- Metal Services

- Materials

- Company

- News

- Contact Us

Added Production for Growing Popularity of Machine-Ready Blanks

TCI Precision Metals today announced the installation of a new 42” CNC double-disc grinding center. Technology advancements built into the new machine improve overall efficiency by more than 50% compared to traditional double-disc grinders, which will help TCI Precision Metals shorten customer lead times, while maintaining close dimensional and flatness tolerances customers have come to expect from the company’s Machine-Ready Blanks.

“At TCI we pride ourselves on producing short run and production quantities of close tolerance, dimensional and flat, pre-machined blanks that are ready to go directly from receiving to finished machining. Producing machine-ready blanks that are consistently flat, square, and parallel is harder than many people think; it requires as much craftsmanship as technology to get it right. Our new 42” CNC double-disc grinding center helps us increase efficiency and better serve our customers,” said Ben Belzer, President of TCI Precision Metals.

The new grinding center was configured by C&B Machinery, New Hudson, MI, and is built on a Gardner model, double-disc reciprocating grinding platform, complemented with the latest in machine logic and motion control automation. Upgrades include a Fanuc controller, and dual 60hp grinding spindle motors, each with operator selectable independent variable speed control, driving two 42” abrasive wheels.

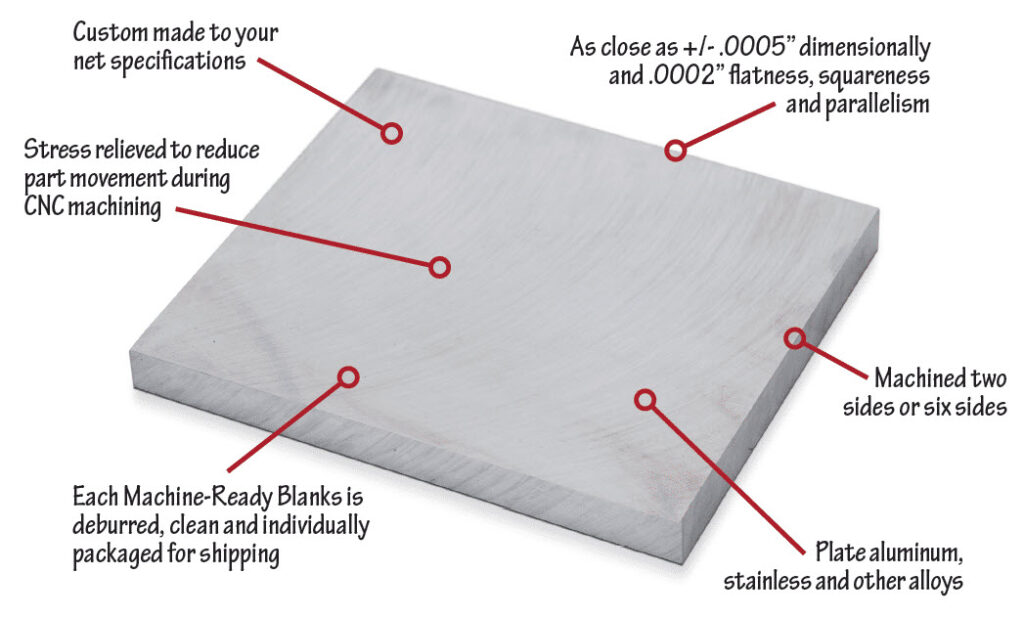

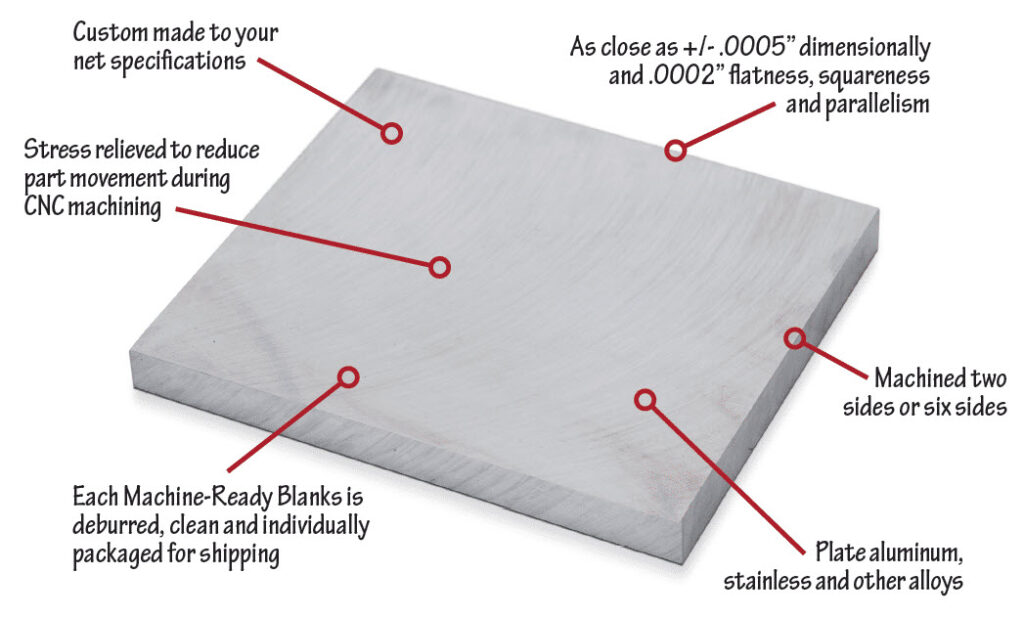

Machine-Ready Blanks from TCI Precision Metals help shops shorten setup time, reduce scrap, and increase overall throughput up to 25% by eliminating material prep.

Ready-to-ship blanks can be ordered online for same-day or next-day shipping, and arrive square, flat and parallel within ± .002” of specified dimensions all around. Custom made-to-order blanks are made to customer specifications and are guaranteed as close as +/- .0005” dimensionally and as close as .002” flatness.

“A good portion of our business is producing flat blanks in various shapes and sizes. This is attributed to the fact that we can hold tight tolerances, both dimensionally and flatness. Our production process also relieves material stress, which reduces the chance of part movement or warping during final machining, especially with thin materials,” said Belzer.

Founded in 1956, TCI Precision Metals is a family-owned, wholesale, Machine-Ready Metals Distributor, producing precision cut parts and Machine-Ready Blanks from aluminum, stainless steel, and other alloys. Sawing, Waterjet Cutting, Grinding, Milling and Finishing operations with the added benefit of being a plate and sheet distributor make TCI Precision Metals a one-stop shop for value-added metal services. TCI Precision Metals offers customers rough CNC milling and turning services when large amounts of material need to be removed or features added to solid parts or castings. Complete-to-print components can also be produced. TCI serves the needs of the medical, oil & gas, aerospace, industrial equipment, defense, food packaging, semiconductor, and many other industries.

For many manufacturers, the first step in a machining operation is to square off the blanks before moving on to machining part features. Keeping the workpieces in a production line as similar as possible is vital, as variances in dimensions can lead to machining errors or automation failures. This is a time-consuming, but necessary...MORE

READY TO SHIP BLANKS

Our Standard Machine-Ready Blanks ™ are pre-configured in hundreds of dimension/alloy combinations. Each precision Standard Blank arrives square, flat and parallel within ± .002”, ready to load directly into your machining centers. Standard Machine-Ready Blanks are available in a wide range of materials and sizes with quick delivery for short and long runs.

Our ready-to-ship precision blanks are available online or through catalog distribution partners. Our distributors carry stock, so you can have most parts next day. More...

TCI Precision Metals will be showing its precision Machine-Ready Blanks capabilities to customers at IMTS 2022, McCormick Place, Chicago, IL, September 12-17, 2022, West Building, Booth #432123.

Machine-Ready Blanks from TCI Precision Metals help shops shorten setup time, reduce scrap, and increase overall throughput up to 25% by eliminating material prep. Machine-Ready Blanks are guaranteed to arrive machine-ready for production, with standard size blanks in low quantities ready for immediate shipping, or custom made-to-order blanks in production quantities can be ordered for quick turnaround. More...

" from TCI Precision Metals help shops shorten set-up time, reduce scrap and increase overall throughput up to 25% by eliminating material prep," said a company spokesperson. " are guaranteed to arrive machine-ready for production, with standard size blanks in low quantities ready for immediate shipping, or custom made-to-order blanks in production quantities can be ordered for quick turnaround." More.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and individually packaged to avoid damage during shipping. Ready-to-ship blanks can be ordered online for same-day or next-day shipping, and arrive square, flat and parallel within ± .002" of specified dimensions all around. Custom made-to-order blanks are made to customer specifications and are guaranteed as close as +/- .0005" dimensionally and as close as .0002" flatness, squareness and parallelism.

"Customers can use the time they previously spent in set-up and prep for more productive use of CNC machining centers, adding to their bottom-line profitability. And with our ability to consistently produce close tolerance, flat blanks, part movement is reduced, improving overall quality," said Ben Belzer, President of TCI Precision Metals.

"TCI is offering new customers an opportunity to try machine-ready blanks on their next job with an IMTS trial promotion," said the spokesperson. "Customers ordering ready-to-ship blanks online will receive 15% off their first order by entering code BLANKS in the coupon field at checkout. Customers considering made-to-order blanks in production quantities can receive a free sample blank made to their exact specifications along with their estimate. Restrictions apply, so ask your TCI sales representative for more information."

Machine-Ready Blanks from TCI Precision Metals

Ready to Ship or Custom Made to Order

IMTS, Booth W-432123

Machine-Ready Blanks from TCI Precision Metals help shops shorten setup time, reduce scrap, and increase overall throughput up to 25% by eliminating material prep. Machine-ready blanks are guaranteed to arrive machine-ready for production with ready-to-ship blanks in low quantities available for immediate shipping, or custom made-to-order blanks can be ordered in production quantities with fast turnaround.

TCI Precision Metals will be showing its precision machine-ready blanks capabilities to customers at IMTS 2022, McCormick Place, Chicago, IL, September 12-17, 2022, west building, booth 432123.

Machine-Ready Blanks from TCI Precision Metals help shops shorten setup time, reduce scrap, and increase overall throughput up to 25% by eliminating material prep. Machine-ready blanks are guaranteed to arrive machine-ready for production, with standard size blanks in low quantities ready for immediate shipping, or custom made-to-order blanks in production quantities can be ordered for quick turnaround.

Precision blanks eliminate the need for in-house sawing, grinding, flattening, squaring operations, and outside processing. Each blank arrives deburred, clean, and individually packaged to avoid damage during shipping. Ready-to-ship blanks can be ordered online for same-day or next-day shipping, and arrive square, flat and parallel within ± .002” of specified dimensions all around. Custom made-to-order blanks are made to customer specifications and are guaranteed as close as +/- .0005” dimensionally and as close as .0002” flatness, squareness, and parallelism. “Customers can use the time they previously spent in setup and prep for more productive use of CNC machining centers, adding to their bottom-line profitability. And with our ability to consistently produce close tolerance, flat blanks, part movement is reduced, improving overall quality,” said Ben Belzer, President of TCI Precision Metals.

TCI is offering new customers an opportunity to try machine-ready blanks on their next job with an IMTS trial promotion. Customers ordering ready-to-ship blanks online will receive 15% off their first order by entering code BLANKS in the coupon field at checkout. Customers considering made-to-order blanks, in production quantities, can receive a free sample blank made to their exact specifications along with their estimate. Restrictions apply, ask your TCI sales representative for more information.

Founded in 1956, TCI Precision Metals is a family-owned precision manufacturer producing precision machine-ready blanks from aluminum, stainless steel, and other alloys. Sawing, Grinding, Milling, and Finishing operations with the added benefit of being a plate and sheet distributor make TCI Precision Metals a one-stop source for quality aluminum, stainless, and other alloy blanks. TCI Precision Metals offers customers rough CNC milling and turning services when large amounts of material need to be removed or features added to solid parts.

TCI is a warehouse plate and sheet distributor for Alcoa, Kaiser, and Hulamin Aluminum, including 6061, 2024, or 7075 aluminum plate and sheet, stainless steel plate, and other alloys, TCI stocks over 500,000 lbs. of material for quick turn-around on customer requirements.

TCI serves the needs of the medical, oil & gas, aerospace, industrial equipment, defense, food packaging, semiconductor, and other industries.

As Americans, we are truly free and will defend that right at all costs. For me personally, watching what is taking place in Ukraine emphasizes just how precious this right is. The people of Ukraine have lived both ways, previously under the oppressive rule of a dictator, and for the last 30-years as a free nation. You tell me, which way is better? These people are willing to risk it ALL to remain independent and most of all, free.

As Americans, we need to trust that our government and military will make the right decisions. As American manufacturers, I ask that we stand together in our resolve to build the best products in the World. Good ole’ American ingenuity and hard work is the backbone of this country and I’m proud to say, Made in America.

Freedom builds pride, inspires quality, and creates a culture that is worth fighting for; and the people of Ukraine know that now more than ever.

The economic effects from the war in Ukraine will have a global reach for sure. We need to put the health and welfare of the Ukrainian people top of mind and suck it up when it comes to any inconveniences we might encounter as a result of economic sanctions or other supply chain issues that may result from the conflict.

Planning is going to be key for the next several months. At TCI we continue to make commitments to increased inventory levels to help keep your production lines moving. For your part, it would be very helpful to communicate with us as far in advance as possible on upcoming materials needs. If we work together, we will overcome economic and supply chain challenges.

Current and Future Challenges

Together, we can work through all challenges.

Thanks for reading.

-Ben

This quote can be traced back to Abraham Lincoln, a wise man indeed. The premise is sound and supports a bias for action to realize opportunity, or even the notion of build it and they will come. In today’s manufacturing economy we have access to a lot more data than good ol’ Abe had back in the day. Shops can gather information to make educated decisions, but success is still dependent on one’s ability to execute, jumping in with both feet and taking the lead.

At times it is difficult for some shops to commit, especially given the current economy that seemingly defies logic in many ways. But victory belongs to the bold; those who can identify an opportunity and seize it. And a good place to start is with educated predictions for what the New Year has in store. Here is a selection of viewpoints from pundits across several industry segments:

We all need to do our homework, pick our battles, draw up our plans, and EXECUTE. Already have too much on your plate? Hogwash! You might need to be more efficient, in other words, do more with what you already have in place. This is something we are good at; we help shops become more efficient, leaner, by helping them increase throughput without increasing overhead.

What you do with the information provided is up to you, but regardless, I wish you a healthy, happy, and prosperous 2022. Let me know if we can help.

Thanks for reading –

Ben

TCI Precision Metals has introduced close-tolerance, Machine-Ready for Production (MRP) materials. The made-to-order blanks eliminate the need for in-house sawing, grinding, flattening, and squaring operations and outside processing.

Each blank arrives deburred, clean, and to the customer’s net specifications as close as +/-0.0005 in. dimensionally and 0.002-in. flatness, squareness, and parallelism. Four types are available: flat, block, dovetail, and feature-added. More...

TCI Precision Metals recently announced support for lights out manufacturing with close tolerance materials that are Machine-Ready for Production (MRP) Guaranteed. MRP Blanks are custom made to order and eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and to the customer’s net specifications as close as +/- .0005” dimensionally and as close as .002” flatness, squareness, and parallelism. Ready to go from receiving to machining. More...