- Home

- Browse Catalog and Order Now

- Ready to Ship Blanks

- Made to Order Blanks

- Aluminum & Steel Custom Vice Jaws

- Metal Services

- Materials

- Company

- News

- Contact Us

TCI Precision Metals, Gardena, California, announced support for lights out manufacturing with close tolerance materials that are Machine-Ready for Production (MRP) Guaranteed. MRP Blanks are custom made to order and eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and to the customer’s net specifications as close as +/- .0005” dimensionally and as close as .002” flatness, squareness, and parallelism. Ready to go from receiving to machining. More...

TCI Precision Metals announces support for lights out manufacturing with close tolerance materials that are Machine-Ready for Production (MRP) Guaranteed. MRP Blanks are custom made to order and eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and to the customer’s net specifications as close as +/- .0005” dimensionally and as close as .002” flatness, squareness, and parallelism. Ready to go from receiving to machining.

Shops can choose from four different types of MRP Blanks to best suit their machining centers and established processes. 1) Flat Blanks are made FLAT to +/-.002″ and designed to stay that way. Parts arrive stress free to avoid movement, or potato chipping, during machining; 2) Block Blanks are close tolerance square, flat and parallel precision blanks that are custom made and arrive ready to go from receiving to machining; 3)Dovetail Blanks maximize 4-, and 5-axis milling throughput with custom sized material that includes a pre-machined dovetail to match the brand and model of dovetail work holding to be used; 4) Feature-Added Blanks have custom features added to save even more time – roughing, stepping, hog outs, drill, bore, turn, mill and more.

Flat Blanks are made FLAT to +/-.002″ and designed to stay that way. Parts arrive stress free to avoid movement, or potato chipping, during machining.

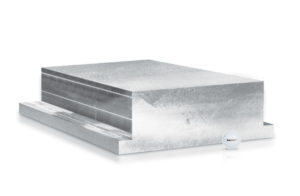

Block Blanks are close tolerance square, flat and parallel precision blanks that are custom made and arrive ready to go from receiving to machining.

Dovetail Blanks maximize 4-, and 5-axis milling throughput with custom sized material that includes a pre-machined dovetail to match the brand and model of dovetail work holding to be used.

Feature-Added Blanks have custom features added to save even more time – roughing, stepping, hog outs, drill, bore, turn, mill and more.

Each MRP Blank arrives deburred, clean, and individually packaged; ready to go from receiving to machining.

“MRP Blanks are consistent part-to-part and suitable for lights-on, human interaction, lights-off robotic handling, or anywhere in between,” said Ben Belzer, President of TCI Precision Metals. “Shops are reporting increases in throughput of 25% and more using MRP Blanks. It really comes down to improving both productivity and quality, lights-on or lights-out.”

MRP Blanks are produced and shipped fast. Orders can be delivered all at once or just-in-time to match customer production schedules.

With prices at historically high levels, a sudden drop would ordinarily be a major concern throughout the supply chain, but most of the participants don’t envision such a scenario unfolding. “We’re under the assumption, from talking to the mills, that it won’t subside for quite a while. We’re planning on the increases continuing through the end of the year and into early next year,” Belzer says.

All of this leaves the domestic mills running at or near capacity, particularly on the flat-rolled side. They must just to keep up with strength in most of their end markets, save aerospace...More

TCI Precision Metals has installed a second OMAX 80X waterjet machining center at its facility in Gardena, Calif. The new machine is the second waterjet added in the last 12 months to keep up with growing demand for precision machine-ready blanks and other specialty parts.

“Our recent investments in both sawing and waterjet cutting equipment have paid off big for our customers by helping us shorten lead time and improve on time delivery. Most of our machine-ready blanks orders are for either aluminum or stainless steel alloys,” said Ben Belzer, president of TCI Precision Metals...More

TCI Precision Metals has announced the installation of its second OMAX 80X waterjet machining center. The new machine is the second waterjet added in the last year to keep up with growing demand for precision Machine-Ready Blanks and other specialty parts.

"Our recent investments in both sawing and waterjet cutting equipment...More

These are strange times we are living through for sure, with seemingly new challenges around every corner. So, the current global supply chain issue should not be a big surprise for any of us. How we choose to handle it is another thing; we can all panic and let fear and uncertainty dictate, or we can work together and plan our way through it.

The pandemic has affected mills with lack of capacities and labor constraints, and they have been slow to ramp up to the high demands during the recent manufacturing highs. Base metal pricing has increased more quickly than anything we’ve seen in decades, and it has increased sheet and plate prices in virtually every metal category, from aluminum to steel, to copper and more. In fact, cooper is becoming a precious commodity with some predicting violent price swings as high as $20 a pound in the face of dwindling supply, while demand continues to be driven by production of electric vehicles.

Many are calling the current situation a bubble, one that will be short lived as soon as supply catches up with demand. Some are optimistic that supply will catch up by mid-2022, and others more worried are looking at least a year out. Right now, nearly all manufacturing sectors are strong with increasing demand. None of us want to find ourselves without materials to fulfill orders or holding the bag with excessive inventory acquired at extremely inflated prices only to have the bubble burst and prices freefall.

In my opinion, the key to all of us weathering this supply shortage effectively is planning, cooperation, and communication. We all need to work together and consider each other’s position within the whole value chain. Extended forecasting needs to better than ever, up and down the line, to take into consideration possible materials shortages and slower than normal delivery. At TCI we continuously review inventory levels to ensure availability for our entire customer base. We’ve also worked directly with our customers’ purchasing departments to forecast upcoming needs so we can ensure a continuous supply. Add to that our recent investments made in capital equipment, including a digitally controlled precision plate saw and a second OMAX waterjet machining center that have greatly increased our efficiency and timeliness when it comes to supplying Machine-Ready Blanks. These investments allow us a better yield, which is additional insurance against material shortages, and allows us to pass these savings along.

We are asking customers to give us as much notice as possible by sharing forecasts and placing orders early. Looking further out with respect to your materials needs lets us combine our capabilities, buying power, warehousing, and logistics to provide you with just-in-time materials.

The more information we have regarding your expectations the better partner we can be. Together, we can match your production and corresponding materials needs against the rising or lowering tides of materials availability and cost.

Don’t panic, we will get through this materials shortage, together.

Thanks for reading –

Ben

TCI Precision Metals, Gardena, Calif., a family-owned, value-added metal services distributor, has announced the installation of its second OMAX 80X waterjet machining center. The new machine is the second waterjet added in the last 12 months to keep up with growing demand for precision machine-ready blanks and other specialty parts...More

TCI Precision Metals has announced the installation of its second OMAX 80X waterjet machining center. The new machine is the second waterjet added in the last twelve months to keep up with growing demand for precision Machine-Ready Blanks and other specialty parts...More

I find it interesting to hear how different shops quantify investments in new technology, equipment, and emerging processes that promise to reduce cycle time, increase spindle time, or otherwise provide improvement to the status quo of production machining. Anything new that requires an ounce of change in process, regardless of stated benefits, are typically vetted in two camps, the naysayers, and the believers. Depending on which side you find yourself on there are plenty of variables in manufacturing to argue whether a new product or service is good or bad for business. That said, there is rarely a single right answer and ultimately you need to decide what is right for your shop.

Assessing whether a product or service fits within your process is the easy part; justifying the investment and measuring the return is what will tell you whether you are making more money or just trading dollars. In my opinion, it is important to consult every department in your organization before investing in any product or service that influences process in any way. This will help avoid what I like to call the ‘Focus Trap.’ You focus so much on justifying a new product, service, or process that you fail to realize potential upstream or downstream ramifications that can easily cancel the positive ROI you are after. So, while focused improvement, with metrics to support it, can be good the bottom line is the bottom line. I like to look at both net gains at the point of implementation as well as positive effects to our overall business.

At TCI we present and sell our Machine-Ready Blanks to manufacturers on the bases of defendable value points beyond the obvious benefit of eliminating material prep. We encourage customers to do their homework and consider how Machine-Ready Blanks can affect their whole business:

Thanks for reading –

Ben

https://www.youtube.com/watch?v=81LZFlZFGd8

While typical CNC machines move in 3-axes (X, Y, and Z), 5-axis machines add two rotary axes, which opens up many more opportunities and benefits surrounding machining productivity gains:

Though the benefits are many, there is still one issue that holds 5-axis machining back from being even more efficient, effectively clamping to a single surface. Dovetail work holding fixtures are one of the best methods of securing a part by a single surface, but they to present a challenge. Every part must first be machined to add a dovetail feature before being 5-axis machine-ready. This takes time and detracts from some of the efficiency gains promised by 5-axis machining.

A good solution to this dilemma is Dovetail Machine-Ready Blanks from TCI Precision Metals.

Dovetail Machine-Ready Blanks are custom produced to your specifications and are Machine-Ready – order from one to thousands with quick turnaround. Each Blank includes a precision Dovetail feature to match the brand and model of your specified fixture and arrives ready to go from receiving directly into your 4- and 5-axis CNC machining centers. With Dovetail Machine-Ready Blanks the full efficiency and added productivity of 5-axis machining is realized.

For more information or to request a quote contact us.

-Thanks for reading