Lean Process Mapping for Machining Materials

Purpose

The following process guide is designed to identify value-added and non-value-added materials steps to improve machining operations, eliminate waste, and streamline material flow for improved efficiency, cost reduction, and consistent quality.

Once steps one through eight are completed, compare your areas of improvement to the benefits of Machine-Ready Blanks (listed at the end of this guide) to determine if they are a suitable fit to improve your manufacturing process.

Many shops report increases in efficiency and overall throughput of 25% or more when using Machine-Ready Blanks.

Step 1: Define Scope and Objectives

Select the machining process or material flow to map (e.g., raw material to finished part).

Clarify objectives: reduce lead time, lower scrap, improve machine utilization, standardize workflow.

Step 2: Gather Baseline Information

Walk the process ("go to gemba").

Collect key data:

Material types and starting formats (bar, billet, casting, plate).

Process sequence (cutting, turning, milling, grinding, finishing).

Setup/changeover times.

Cycle times per operation.

Wait/queue times between steps.

Inventory levels (WIP, raw stock, finished goods).

Transport distances.

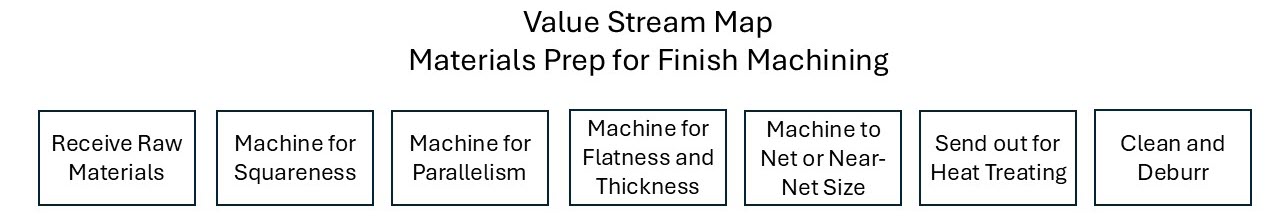

Step 3: Map Current State

Draw a process map from material receipt to finished part shipment.

Capture:

Process steps (value-added).

Inspections, rework, delays (non-value-added).

Material handoffs and movements.

Information flow (work orders, travelers, ERP updates).

Use lean symbols (manual process, machine process, inventory, transportation, delay).

Step 4: Identify Waste (The 8 Wastes in Machining)

Defects: scrap parts, rework.

Overproduction: making more than required.

Waiting: idle machines or operators.

Non-utilized talent: underuse of operator skills.

Transportation: unnecessary movement of materials.

Inventory: excess WIP or raw stock.

Motion: inefficient operator/tool movements.

Extra-processing: redundant setups, unnecessary machining passes.

Step 5: Develop Future State Map

Redesign the process to reduce or eliminate waste.

Strategies:

Cellular machining or one-piece flow where possible.

Optimize setups with SMED (Single Minute Exchange of Dies).

Standardize tooling and fixturing.

Reduce handling by integrating operations (multi-axis machining, palletization).

Apply pull scheduling (Kanban).

Place inspection at the point of machining (in-process probing).

Step 6: Create an Action Plan

List prioritized improvement opportunities.

Assign owners and deadlines.

Define metrics (cycle time reduction, scrap %, machine utilization, on-time delivery).

Step 7: Implement and Monitor

Pilot improvements on a single process or material family.

Track KPIs against baseline.

Adjust and standardize successful practices.

Step 8: Sustain and Improve

Standardize work instructions.

Train operators and supervisors.

Establish regular review cycles.

Keep visual process maps updated.

Promote a culture of continuous improvement (Kaizen).

Key Tip: Start small—map a single machining cell or material family first. Achieve a quick win, then expand lean process mapping to broader operations.

Lean Materials Solution: Precision Machine-Ready Blanks

Machine-Ready Blanks from TCI Precision Metals make materials processing leaner? Consider the following benefits to determine if they are a good fit for your business.

Prepping material for finish machining can account for as much as 50% of the total time on the job. Custom Machine-Ready Blanks from TCI Precision Metals eliminate material prep, shorten setup time, reduce scrap, improve quality, and increase overall machining throughput by 25% or more – all without increasing overhead.

Custom Machine-Ready Blanks are made to order and arrive ‘machine-ready.’ Typically, they are square, rectangular, or round stock milled to your custom net specifications. They can be produced as close as +/-.0005” dimensionally and as close as .002” in flatness, squareness, and parallelism. Machine-Ready Blanks eliminate the need for squaring up the material prior to finishing the part. Flatness is especially important as it reduces the tendency for part movement during the machining process.

By starting a production job with Machine-Ready Blanks, you reduce the need for specialized machines or tying up machines that are better served performing other operations. Bottlenecks created by time-consuming setup and squaring operations are avoided, resulting in even more time being saved. This increases shop capacity without adding overhead. Machine-Ready Blanks are deburred, clean, and vacuum packaged to avoid damage during shipping – ready to go directly from your receiving dock to your CNC machines.

- Increase production throughput by 25% or more

- Eliminate in-house material prep time

- Produce more parts faster

- Reduce bottlenecks

- Improve quality

- Reduce scrap

For more information about Machine-Ready Blanks, CONTACT US

To request a quote, CLICK HERE