- Home

- Browse Catalog and Order Now

- Ready to Ship Blanks

- Made to Order Blanks

- Aluminum & Steel Custom Vice Jaws

- Metal Services

- Materials

- Company

- News

- Contact Us

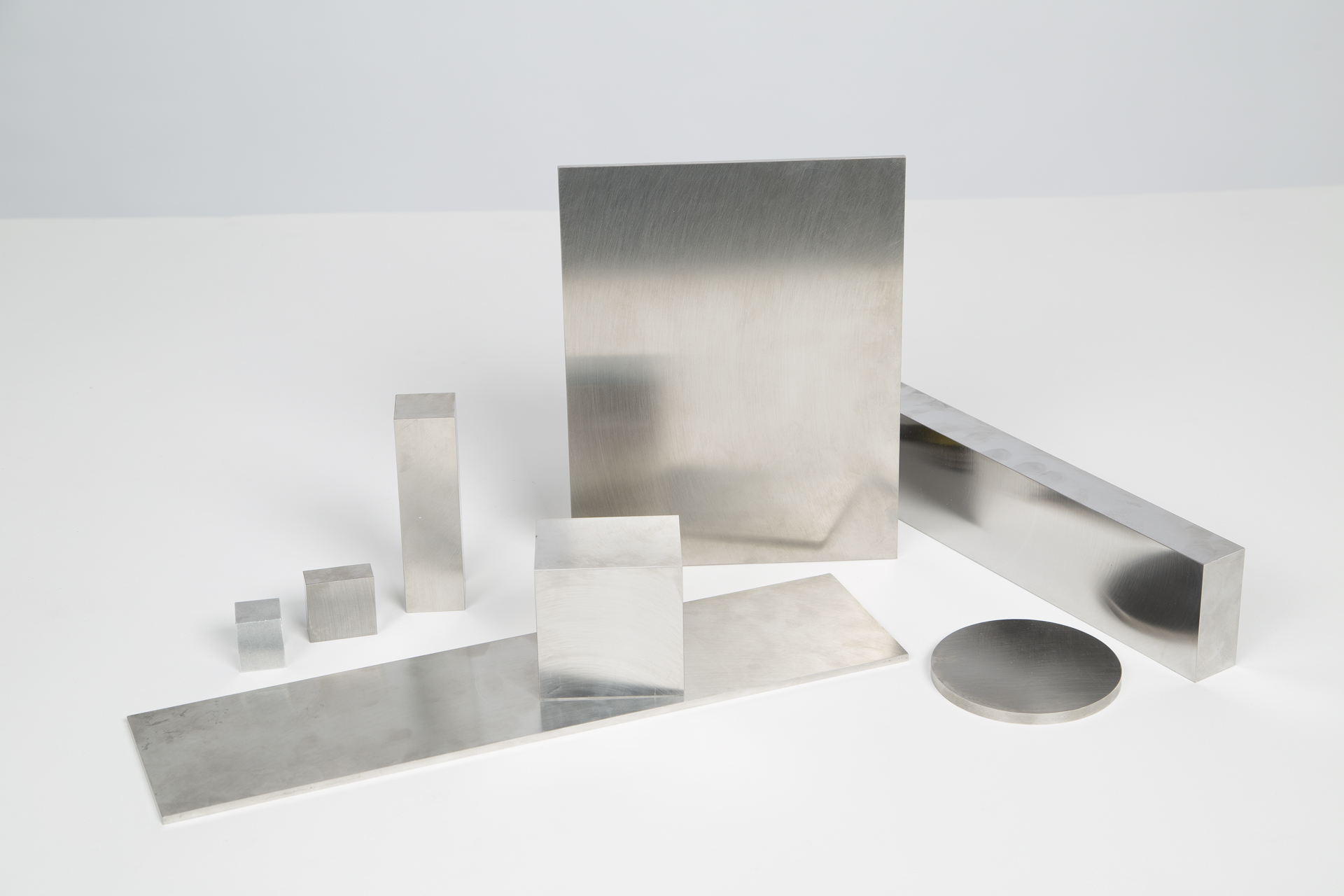

Our Standard Machine-Ready Blanks ™ are pre-configured in hundreds of dimension/alloy combinations. Each precision Standard Blank arrives +/- .002" on machined dimensions and square, flat and parallel as close as ± .002”, ready to load directly into your machining centers. Standard Machine-Ready Blanks are available in a wide range of materials and sizes with quick delivery for short and long runs.

Our ready-to-ship precision metal blanks are available online or through catalog distribution partners. Our distributors carry stock, so you can have most parts the next day.

In addition to our online store, our ready-to-ship precision stainless steel and aluminum blanks are also available for immediate delivery, at your preferred catalog distributor.

Not all sizes are available at all distributors. To request custom sizes and larger production quantities, please Request a Quote and we will create a customized part proposal.

All parts come with full mill certification and are precision ground and milled to +/-.002″ on all sides.

Improve Quality

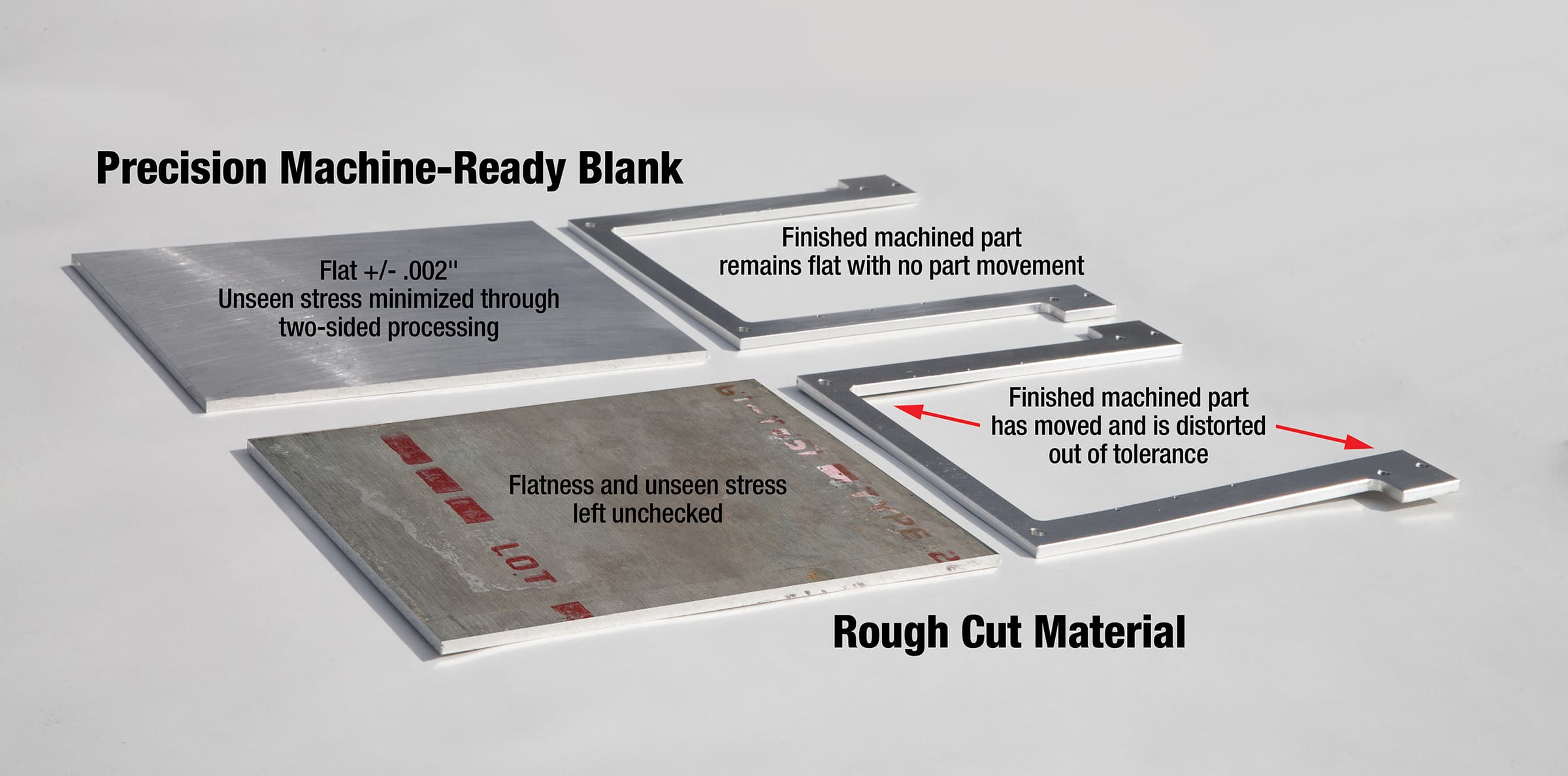

Ready-to-ship precision metal blanks are made flat and designed to stay that way. Flatness is especially important as it eliminates the tendency for part movement during the machining process, especially with large surface area parts.

Demand for flat material that resists movement during machining is high for two reasons, one, part movement can turn parts into scrap, and two, creating flat material, on your shop floor, that resists movement is harder than many people might think. The top and bottom surfaces of machine-ready blanks are processed simultaneously, which maintains flatness and reduces hidden stress introduced into the material when it was milled.

All Standard Machine-Ready Blanks arrive deburred, cleaned, and packaged to eliminate the possibility of damage in handling and shipping.

When Even Tighter Tolerances are Required

Custom Machine-Ready Blanks are available through special order. They provide all the benefits of standard blanks but are precision ground and/or milled to your net specifications and can be furnished as close as +/-.0005˝ dimensionally and as close as .0002˝ in flatness, squareness and parallelism.

Our ready-to-ship precision metal blanks eliminate the need for specialized machines or tying up machines that are better served performing other operations. Bottlenecks created by time-consuming setup and squaring operations are avoided, saving even more time. This increases shop capacity without adding overhead.

Machine-Ready Blanks arrive ready to go directly from your receiving dock onto your CNC machines. By ending prep time and minimizing setup time, your operators and machines get to the high-value work of finish machining, faster.

Consistent tolerances from blank-to-blank reduce operator and machine time spent adjusting setups and work holding fixtures, which saves valuable spindle time.