- Home

- Browse Catalog and Order Now

- Ready to Ship Blanks

- Made to Order Blanks

- Aluminum & Steel Custom Vice Jaws

- Metal Services

- Materials

- Company

- News

- Contact Us

Many of our customers come to us with the issue of trying to keep parts flat during machining.

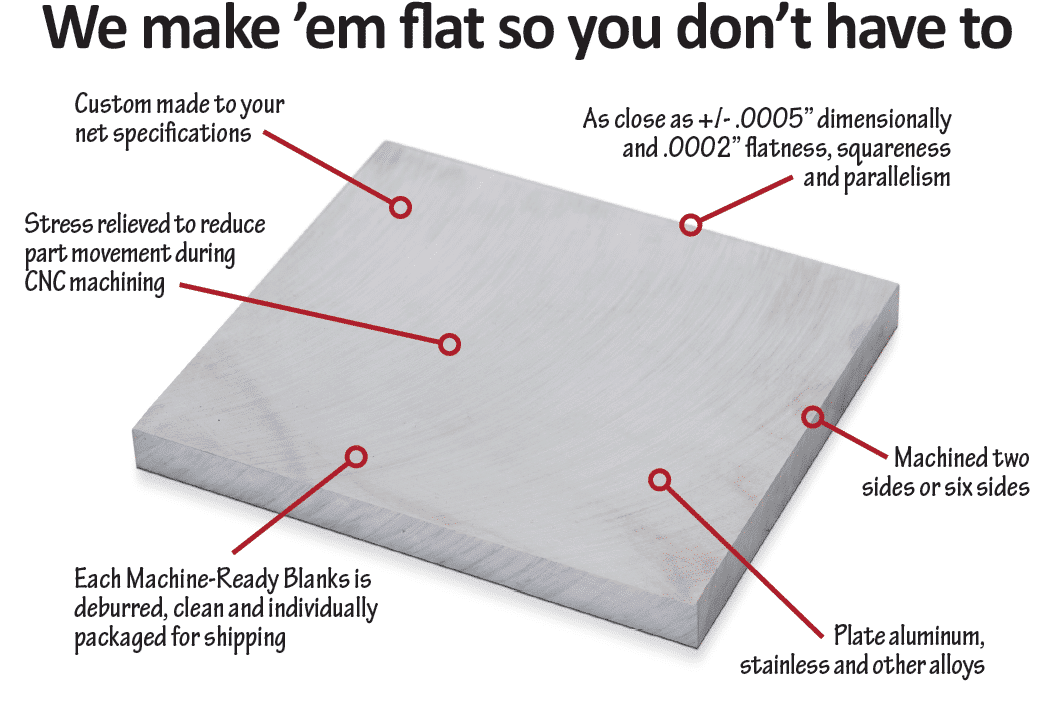

TCI’s specialized flattening and straightening equipment ensures your parts will arrive flat, without twist, without bows, so you have the confidence your parts will not move when you cut your first chip.

Every job is different. Ask our specialists how flat we can hold your parts, so you can use your valuable time finishing the part.

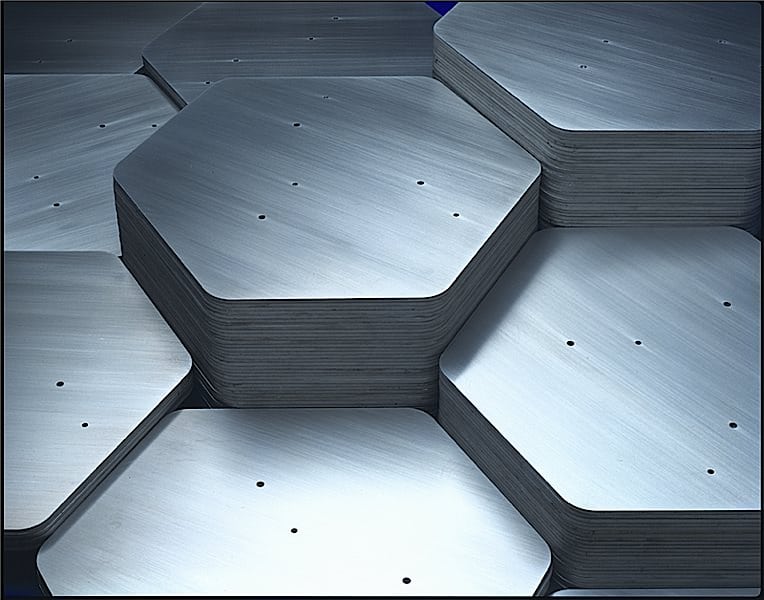

Machine-Ready Blanks free up your high-precision CNC workcenter, to get to what it does best, complex machining. With a pre-prepped part, your operator will simply load, lock and go. Set the part against pins, clamp down, and hit the green button. Simple as that.

What does this mean in the end? THROUGHPUT. Your machine is freed from prepping, and now working on high-dollar finishing activities.

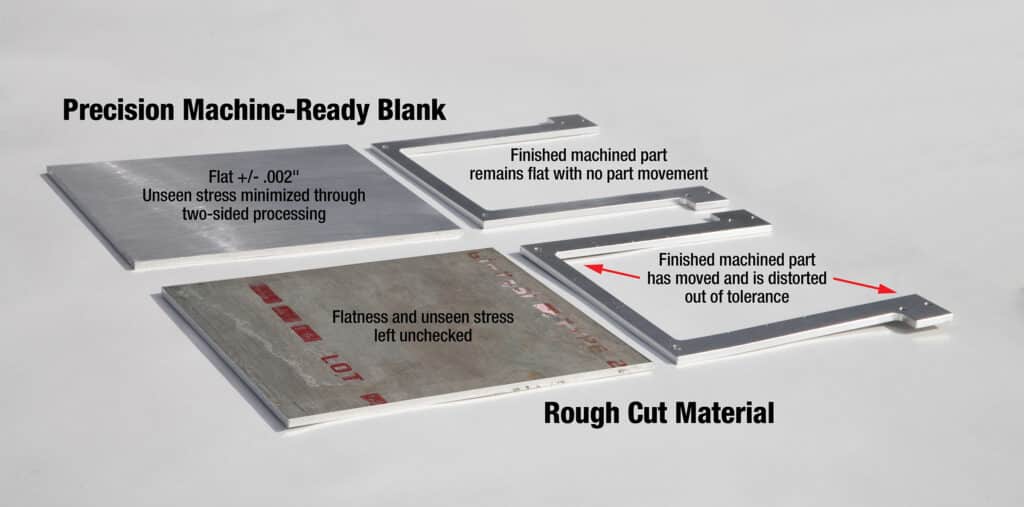

At TCI Precision Metals we produce flat, close tolerance materials every day. Prepping materials that starts out flat and has a greater likelihood of staying flat is harder than it might seem. The process is as much art and craftsmanship as it is science. The fact is, you can not see the residual stress introduced into the material during the manufacturing process, you can only see the results of it as parts start to move. Our process of producing close tolerance blanks produces flat materials that are more likely to stay flat during finish machining.

This is a best practice method for calling out flatness and parallelism, but also clarifying the difference between the two so you are sure to specify exactly what you want.

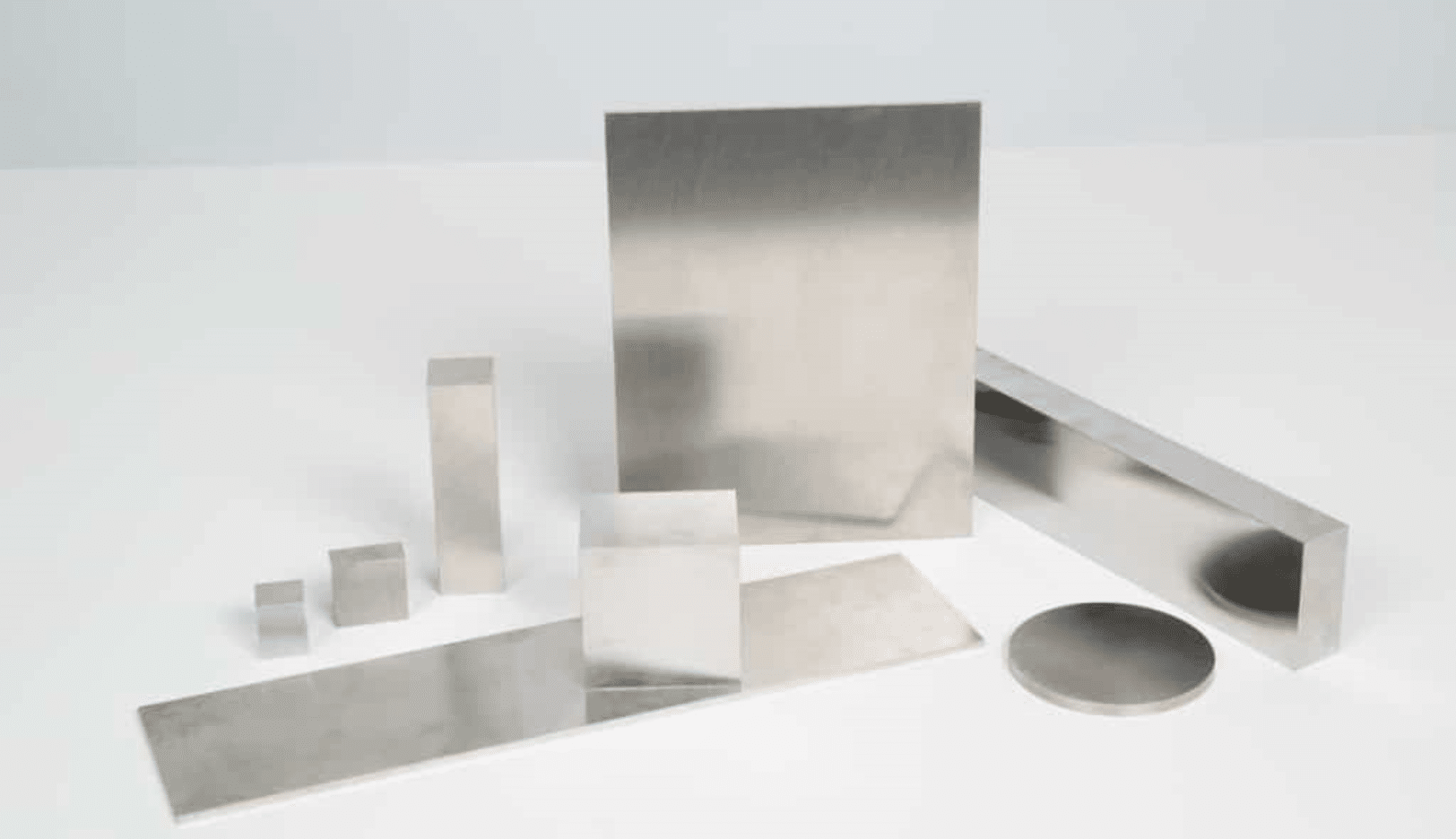

High-quality Flattening, Straightening and Finishing services are provided by TCI through an array of hydraulic, mechanical and abrasive machines, producing close tolerances with superior finishes to 600 grit.

By having TCI grind your material and apply our flattening process, your parts will arrive without stress, will sit flat on your fixtures, and won’t spring as you start cutting.

Example on right:

TCI can provide a uniform surface finish for customers requiring it for scratch-free or cosmetic purposes. Our specialized machine (Timesaver) applies a uniform, one-direction pattern to the part, with use of coated abrasives. This lightly sands the material to create this uni-directional, sanded appearance.

TCI Precision Metals is a mill-direct wholesale plate and sheet distributor and can deliver precision cut parts to your specifications. We also welcome customer supplied material. Let TCI quote your next sawing requirement. We will source the material and saw cut, or provide additional Grinding, or Duplex Milling as required.

Let TCI quote your next flattening and straightening requirement. We will source the material, cut, and provide additional Grinding, or Duplex Milling as required.