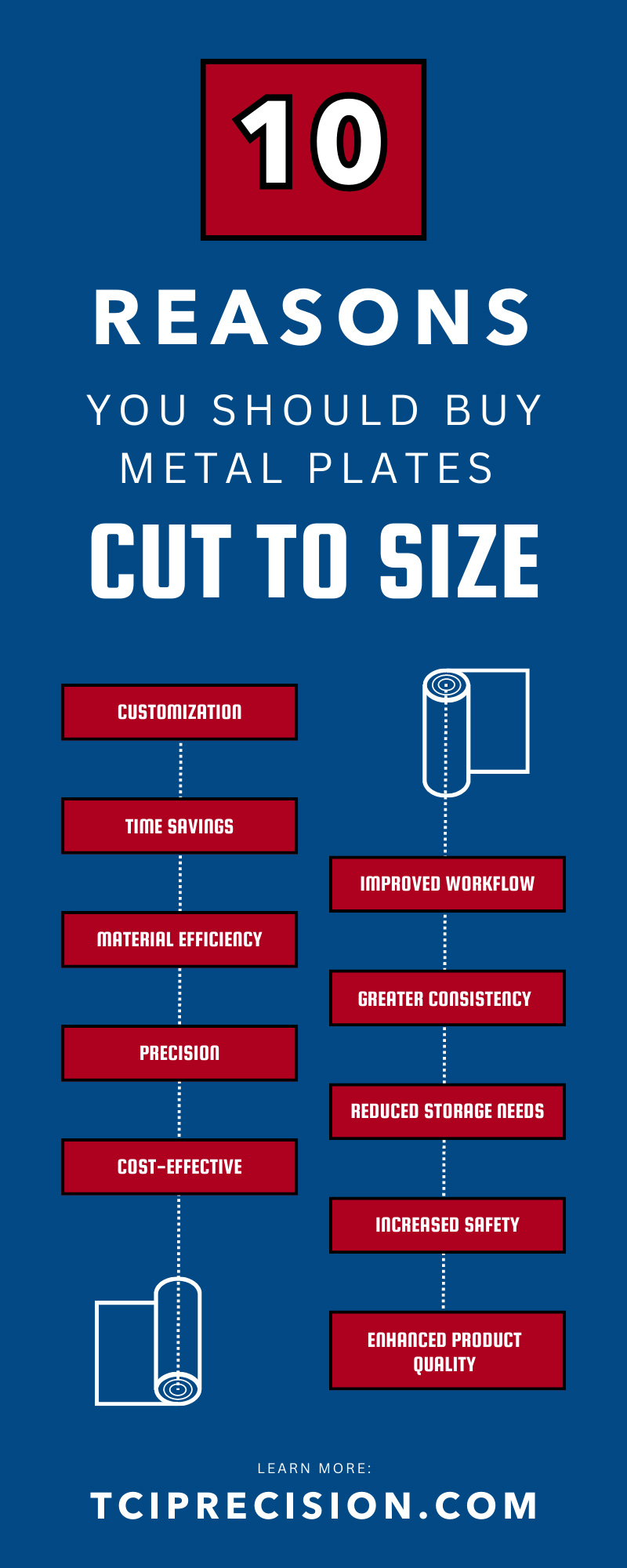

10 Reasons You Should Buy Metal Plates Cut to Size

The precise world of metalworking demands meticulous attention to detail, especially regarding the materials used. Whether your industry is aerospace, automotive, or general manufacturing, the decisions you make during the initial stages of a project will influence its overall success. One crucial decision is to buy metal plates precision cut to size, a game-changing move that can transform the way you operate. Read on to discover ten reasons you should buy metal plates cut to size.

How Metal Plates Are Cut to Size

Before we discuss the many benefits of metal plates cut to size, let’s develop an understanding of how these plates are produced.

Material Selection

The process begins with material selection. Various metals may be used for a project depending on its specifications; options include steel, aluminum, brass, or other alloys. It's crucial to choose a metal that can withstand the cutting process and meet the project's strength and flexibility requirements. The chosen metal plate is then prepared for the cutting process.

Cutting Techniques

Various cutting techniques are employed based on the metal type and the required precision. Some common methods include laser cutting, water jet cutting, and plasma cutting.

Laser cutting uses a concentrated, high-powered laser beam to cut through the metal. It offers a high degree of accuracy and is excellent for detailed, complex cuts.

Water jet cutting employs a high-pressure stream of water, sometimes mixed with abrasive substances. This method is perfect for metals that may be affected by the high temperatures of other cutting techniques.

Plasma cutting, on the other hand, uses a hot plasma stream to cut through the metal. It's often used for thick metal plates and allows for rapid cutting.

Machine Setup

Once the cutting method is chosen, the machine is set up. This involves programming the machine with design specifications, which are often created in CAD (computer-aided design) software. The CAD file guides the cutting machine, ensuring precision cuts that match the project requirements.

Cutting Process

During the cutting process, the machine follows the guidance from the CAD file, cutting the metal plate to the exact size required. Continuous monitoring is crucial throughout this stage to ensure the precision and quality of the cut.

Quality Control

After the cutting process, the attending professional conducts a quality control check. This involves measuring the cut pieces against the original specifications. Any deviations are corrected, and the process is adjusted as necessary to maintain high-quality output.

Finishing

The final stage in the process is finishing, which involves deburring and smoothing the cut edges. This step ensures the metal plates are safe to handle and ready for the next stage of the manufacturing process.

Customization

When you opt for metal plates precision cut to size, you sign up for a level of customization that offers unparalleled benefits. These plates are tailored to meet your specific needs, ensuring the materials align perfectly with your project specifications. Instead of adjusting standard-size plates, you begin your project with materials that are the right fit. This direct approach saves time and effort, making your production process more streamlined and effective.

Time Savings

Time is a valuable commodity in the manufacturing world. When you choose metal plates cut to size, you bypass the time-consuming process of additional cutting or resizing. This strategy enhances efficiency, freeing up valuable time in your production cycle. In turn, this helps you adhere to tight schedules, delivering projects on time, and keeping your operations running smoothly.

Material Efficiency

Choosing metal plates cut to size is a wise move when it comes to material efficiency. With this approach, you order exactly what you need, minimizing waste and ensuring maximum utilization of your materials. This cost-effective strategy not only impacts your bottom line positively but also boosts your sustainability efforts by reducing waste.

Precision

Precision is of the utmost importance in any metalworking project. By ordering metal plates cut to size, you ensure the materials you receive meet your project's exact specifications. This precision plays a crucial role in maintaining the integrity of your final product. Metal plates cut to size eliminate the risk of size disparities that could potentially compromise the quality of your work.

Cost-Effective

Although buying oversized standard-size plates and modifying them might seem like a cheaper option initially, consider the hidden costs. The labor costs for additional cutting, tooling, and waste disposal can add up quickly. On the other hand, metal plates precision cut to size are a long-term, cost-effective solution. They streamline your process, reducing labor and tooling expenses while eliminating waste.

Improved Workflow

Streamlining workflow is a significant advantage of metal plates cut to size. By eliminating extra steps from your production process, your workflow becomes more efficient and less complicated. This efficiency can increase productivity, allowing your team to focus more on the intricate details of the project rather than spending time on unnecessary tasks.

Greater Consistency

Consistency is key when it comes to producing high-quality products. With metal plates cut to size, you achieve uniformity across your production line. Every plate arrives with the same dimensions, leading to better consistency in your final products. This consistency can improve your product quality, enhancing your reputation in the marketplace.

Reduced Storage Needs

Having metal plates cut to size also reduces your storage needs. Instead of storing large, standard-size plates, you only need to make room for the exact size required for your job. This can free up valuable space in your facility, making your operations more efficient and organized.

Increased Safety

Safety in the workplace is a top priority. Working with precision stainless steel plates cut to size reduces the need for additional cutting or resizing, which can be a hazardous task. Fewer accidents occur when employees handle materials that have already been cut to the required size, promoting a safer work environment.

Enhanced Product Quality

Ultimately, these advantages all lead to one primary benefit: enhanced product quality. With increased precision, consistency, efficiency, and safety, you can focus more on the production process itself. This attention to detail ensures peace of mind as you move forward with your project.

Now that you know these ten reasons you should buy metal plates cut to size, we hope it's clear that this approach brings a host of benefits. From cost and time savings to precise customization and quality assurance, using metal plates cut to size provides an undeniable edge in your manufacturing process.