5-Axis Machining - A Form of Automation

5-axis machining is a form of automation. Traditional machining methods often involve manually operating machines, where the operator must move and adjust the workpiece and the cutting tool. This process can be time-consuming and error-prone, leading to inconsistencies and increased production costs.

5-axis machining takes automation to a higher level by introducing more advanced and efficient capabilities:

Multi-axis control: 5-axis machining involves the simultaneous movement of the cutting tool along five different axes: X, Y, Z, and two rotational axes (usually A and B or C). This flexibility allows the machine to reach virtually any angle or position required to perform complex cuts and shapes without the need for manual adjustments.

Increased productivity: The ability to move in multiple directions at once enables 5-axis machines to complete tasks faster. In contrast, traditional 3-axis machines may require multiple setups to achieve similar results, leading to increased setup times and reduced productivity.

Enhanced accuracy: Automation through 5-axis machining provides higher precision and consistency compared to manual operations. The computerized control ensures that each cut is performed with the exact specifications provided in the CNC program, reducing the risk of human error and resulting in superior part quality.

Reduction of manual labor: With 5-axis machining, much of the process is automated, reducing operators' need for constant manual intervention. Once the CNC program is set up correctly, the machine can run unattended for extended periods, improving production efficiency.

Complex part manufacturing: 5-axis machines are handy for creating intricate and challenging geometries that may be difficult or impossible to produce using conventional machining methods. This capability enables manufacturers to explore innovative designs and produce high-quality, unique parts.

Cost-effectiveness: Despite the initial investment in 5-axis machining equipment and programming, the overall cost-effectiveness of automation comes into play in the long run. Faster production times, reduced waste, and enhanced part quality can lead to significant cost savings over time.

5-axis machining is a powerful form of automation that revolutionizes the manufacturing industry by providing advanced capabilities, improved productivity, higher precision, and cost-effective solutions for producing complex parts and components.

Machine-Ready Dovetail Blanks

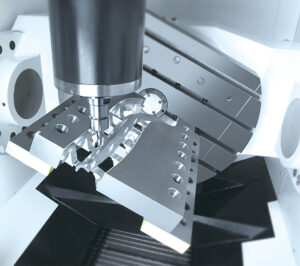

5-axis machining centers are one of the most sought-after machine tool formats today, especially for aerospace applications. The reason is clear; one setup and you are ready to machine five sides. The challenge with this promise of efficiency has always been the need for low-profile, precise, and secure work holding from a single surface. Dovetail work holding fixtures have solved the problem of how to hold the part, but the challenge of material handling and preparation remains. This challenge is solved with Dovetail Machine-Ready Blanks from TCI Precision Metals.

Dovetail Machine-Ready Blanks are produced to the customer's specifications and can be ordered in quantities from one to thousands with a quick turnaround. Each Dovetail Machine-Ready Blank includes a pre-milled Dovetail feature to match the customer’s specified brand and model of work holding fixture and arrives ready to go from receiving directly into 5-axis CNC machining centers. Benefits include:

- Elimination of material prep – one less unnecessary manufacturing operation

- Reduce cycle time, chip-to-chip

- Reduce setup time, including the number of setups

- Better materials inventory management

- Reduced production bottlenecks