Optimizing Automation with the Right Materials Strategy

In today’s competitive manufacturing environment, automation is a critical lever for increasing productivity and reducing costs. But automation alone doesn’t guarantee success—consistency does. At TCI Precision Metals, our materials experts work hand-in-hand with shop floor managers to develop tailored materials strategies that ensure automation runs smoothly from the start.

A successful materials strategy begins well before a part hits the machine. It starts with identifying the right material type for the job and then engineering the pre-production process to match the needs of the automated work cell. This includes essential considerations such as heat treating, part handling, gripping, clamping, and other tooling requirements. Every detail matters because every variable eliminated increases the odds of a predictable and efficient production run.

Once a plan is in place, TCI produces test materials for validation. Only after shop floor approval are full batches of Automation-Ready Blanks produced. These blanks are delivered in sync with Just-In-Time (JIT) production schedules and arrive certified to spec, flat, square, dimensionally accurate, and ready for immediate use in automated cells.

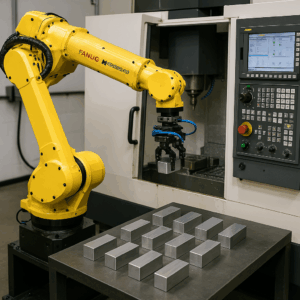

Automation-Ready Blanks from TCI help manufacturers get the most from their investments in CNC machining centers, robotic handling systems, and multi-axis automation platforms. They reduce setup time, eliminate secondary operations, and keep workflows moving without interruption. By engineering consistency into the raw materials themselves, TCI helps ensure that every part starts out right, reducing waste, improving throughput, and unlocking the full potential of automated manufacturing.

If you’re investing in automation, don’t overlook the foundation - your material supply. TCI’s Automation-Ready Blanks may be the missing link between what your shop floor is doing now, and what it is capable of achieving.

Thanks for reading

– Ben