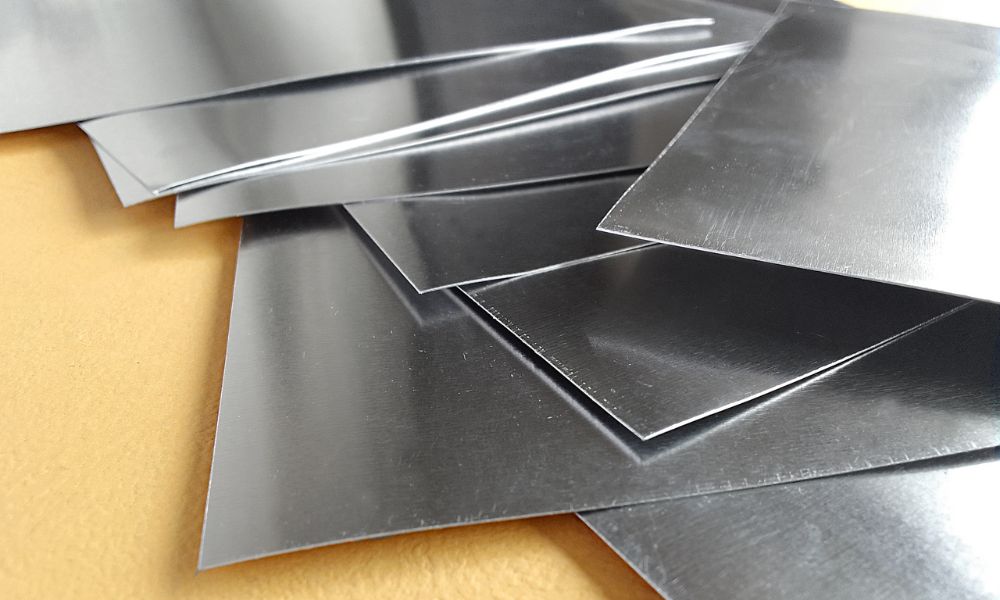

A Guide to Different Grades of Aluminum Blanks

Aluminum is a versatile and lightweight material used in various industries, from aerospace to manufacturing. Different grades of aluminum are available to suit various applications, and each grade has unique properties and characteristics. Read on for a comprehensive guide to different grades of aluminum blanks.

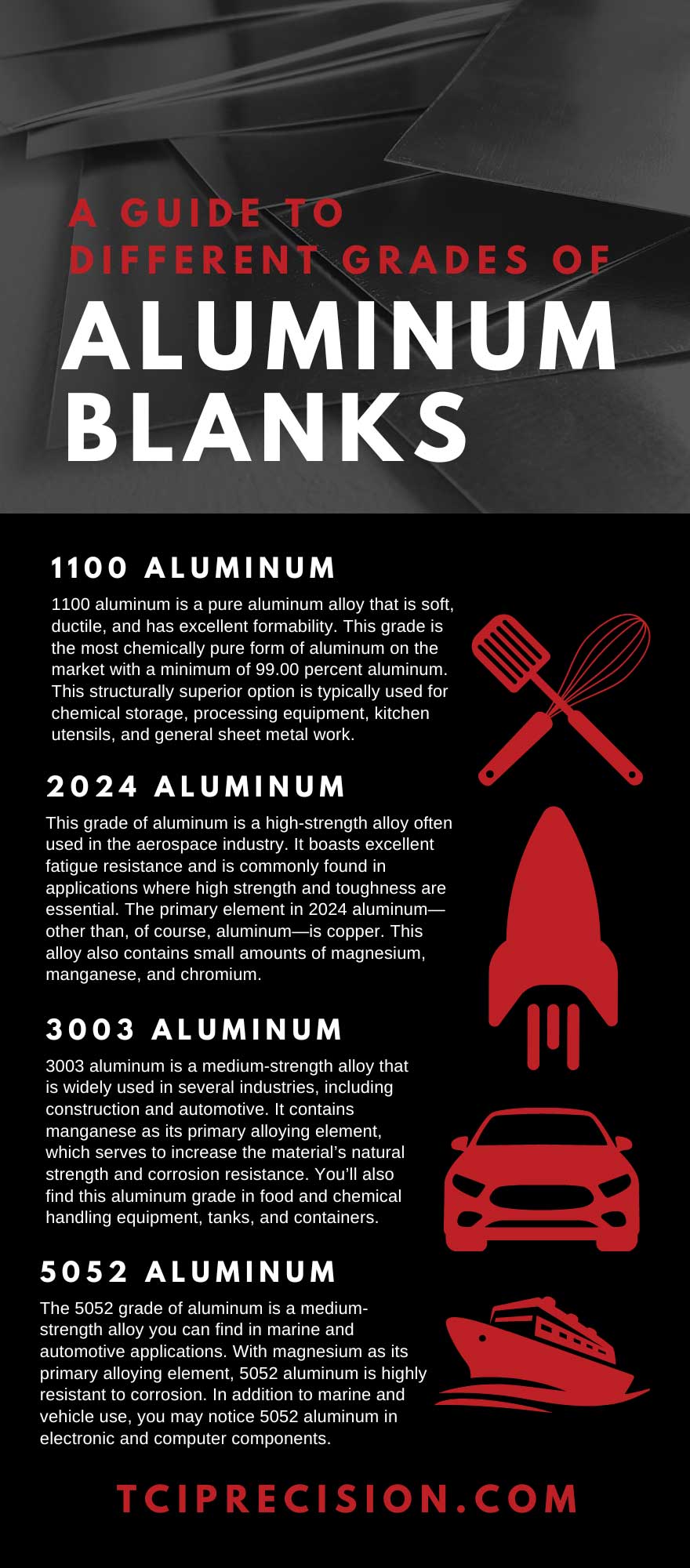

1100 Aluminum

1100 aluminum is a pure aluminum alloy that is soft, ductile, and has excellent formability. This grade is the most chemically pure form of aluminum on the market with a minimum of 99.00 percent aluminum. This structurally superior option is typically used for chemical storage, processing equipment, kitchen utensils, and general sheet metal work.

1100 aluminum is highly malleable, making it easy to form and shape. It also has excellent corrosion resistance, especially when it is anodized. However, 1100 aluminum is soft compared to other alloys, which means that it has a low strength-to-weight ratio. Additionally, 1100 aluminum has a low melting point, limiting its use in high-temperature applications.

2024 Aluminum

This grade of aluminum is a high-strength alloy often used in the aerospace industry. It boasts excellent fatigue resistance and is commonly found in applications where high strength and toughness are essential. The primary element in 2024 aluminum—other than, of course, aluminum—is copper. This alloy also contains small amounts of magnesium, manganese, and chromium.

2024 aluminum’s strength-to-weight ratio is excellent, which is why it is ideal for aerospace applications. It’s important to note that while 2024 aluminum is not without corrosion resistance, it is not as resistant as other aluminum alloys.

3003 Aluminum

3003 aluminum is a medium-strength alloy that is widely used in several industries, including construction and automotive. It contains manganese as its primary alloying element, which serves to increase the material’s natural strength and corrosion resistance. You’ll also find this aluminum grade in food and chemical handling equipment, tanks, and containers.

One of the main benefits of 3003 aluminum is that it’s easy to work with. However, its corrosion resistance does not make it as strong as other alloys, and problems with cracking could arise under certain conditions.

5052 Aluminum

The 5052 grade of aluminum is a medium-strength alloy you can find in marine and automotive applications. With magnesium as its primary alloying element, 5052 aluminum is highly resistant to corrosion. In addition to marine and vehicle use, you may notice 5052 aluminum in electronic and computer components.

Not only does this grade offer excellent corrosion and saltwater resistance, but 5052 aluminum is well-suited for welding and forming applications. That said, since it is a medium-strength alloy, you can easily find options that are stronger.

6061 Aluminum

6061 aluminum is a versatile alloy that contains magnesium and silicon as its primary alloying elements. This grade is best known for its excellent machinability, weldability, and formability—if you’re looking for an all-around winner, 6061 aluminum may be it.

It’s easy to shape this grade into a variety of forms, making it a go-to option across industries. One drawback to be mindful of, however, is that 6061 aluminum has a low melting point. If your applications require placing the aluminum in a high-temperature environment, you may want to find another option.

6063 Aluminum

6063 aluminum contains higher amounts of silicon and magnesium, making it a perfect choice for extrusions and architectural applications. These could include window frames, door frames, and other building components.

With moderate strength, workability, and corrosion resistance, 6063 aluminum is another tried-and-true grade. Although, one thing to look out for is its limited weldability. And you may want to refrain from using this grade in high-stress applications as it could crack.

7075 Aluminum

7075 aluminum is a high-strength alloy often used in aircraft and aerospace applications. You may have encountered this alloy in bike frames and other sports equipment, as it allows for durability without sacrificing weight. 7075 aluminum is also used in firearm parts since it is uniquely suited to withstand the stresses of firing and recoil.

While there are several benefits of this grade, like an ideal strength-to-weight ratio and good heat treatability, you need to factor in that it can be difficult to weld. If you have the right equipment, however, 7075 aluminum can work wonders for you.

Essential Considerations When Choosing a Grade

Let’s take a closer look at some of the factors that will influence your choice when finding the right grade for the job.

Workability

Workability refers to how easily a material can be formed or shaped without cracking or breaking. High workability is ideal for applications that call for extensive forming, such as the automotive and aerospace industries. On the other hand, low workability can be beneficial for applications that require increased strength, such as structural components and support beams.

If you’re looking for grades with high workability, consider 1100, 3003, and 5052. These options are often used for products like cooking utensils, roofing materials, and chemical equipment. 6061 and 7075 aluminum are less workable, but are often used in applications where strength and durability are of the utmost importance.

Weldability

Weldability is all about how easily a material can be welded without creating defects or weakening the material. While aluminum is known for good weldability, some grades are better than others. 1100, 3003, and 5052 are highly weldable, making them ideal for applications that require welding, such as piping, tanks, and other similar structures.

As you may have guessed based on the connections between workability and weldability, 6061 and 7075 are considered less weldable. However, these grades canbe welded—it just takes extra care and skill.

Strength

Strength is an important consideration in many aluminum applications, especially in aerospace, automotive, and industrial components. 6061 and 7075 aluminum are among the strongest aluminum grades available and are commonly used in high-stress applications.

Aluminum grades with lower strength, such as 1100, 3003, and 5052, are often used in applications that don’t require high strength. Regardless of the grade you need, TCI Precision Metals is stocked with ready-to-ship metal blanks for your company’s specific applications. Ready-to-ship blanks are pre-machined to close tolerance, deburred, cleaned, and individually packaged for shipping. Ready-to-ship blanks arrive ready to go directly from receiving to machining, eliminating material prep, reducing scrap, improving quality, and increasing overall machining throughput by 25% or more!

After reading this guide to different grades of aluminum blanks, we hope you have a better understanding of the benefits of each different grade. Here at TCI Precision Metals, we are proud to provide the very best in a wide range of aluminum grades. No matter which one you need for your applications, we can assist you!