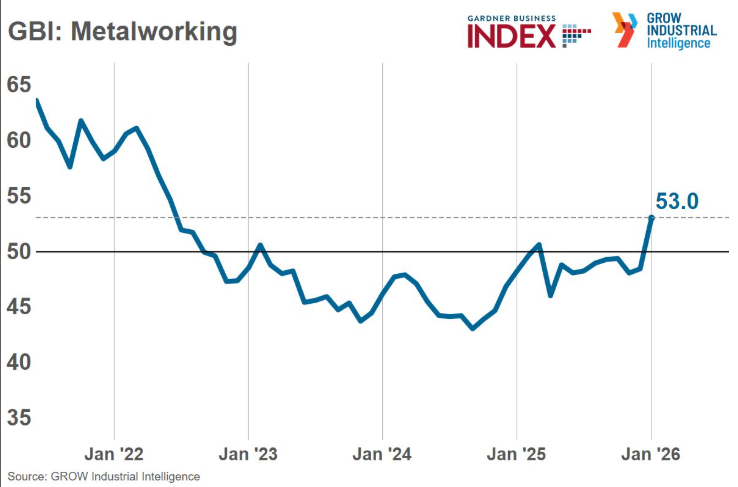

After more than 3-years of contraction and one of the longest slumps in the metalworking industry, things are looking up. Personally, I have felt the energy in the market building over the last few months, and now the January numbers are in and it’s official. The metalworking index is in growth mode at 53%. Now what? […]

- Home

- Browse Catalog and Order Now

- Ready to Ship Blanks

- Made to Order Blanks

- Aluminum & Steel Custom Vise Jaws

- Metal Services

- Materials

- Company

- News

- Contact Us