Choosing Between 6061 vs. 2024 Aluminum Precision Blanks

Choosing the right material for your manufacturing project is critical. In the realm of aluminum precision blanks, two popular choices emerge—6061 and 2024. Though seemingly similar, these two aluminum alloys have distinct characteristics and applications that set them apart. Find out how to choose between 6061 and 2024 aluminum precision blanks.

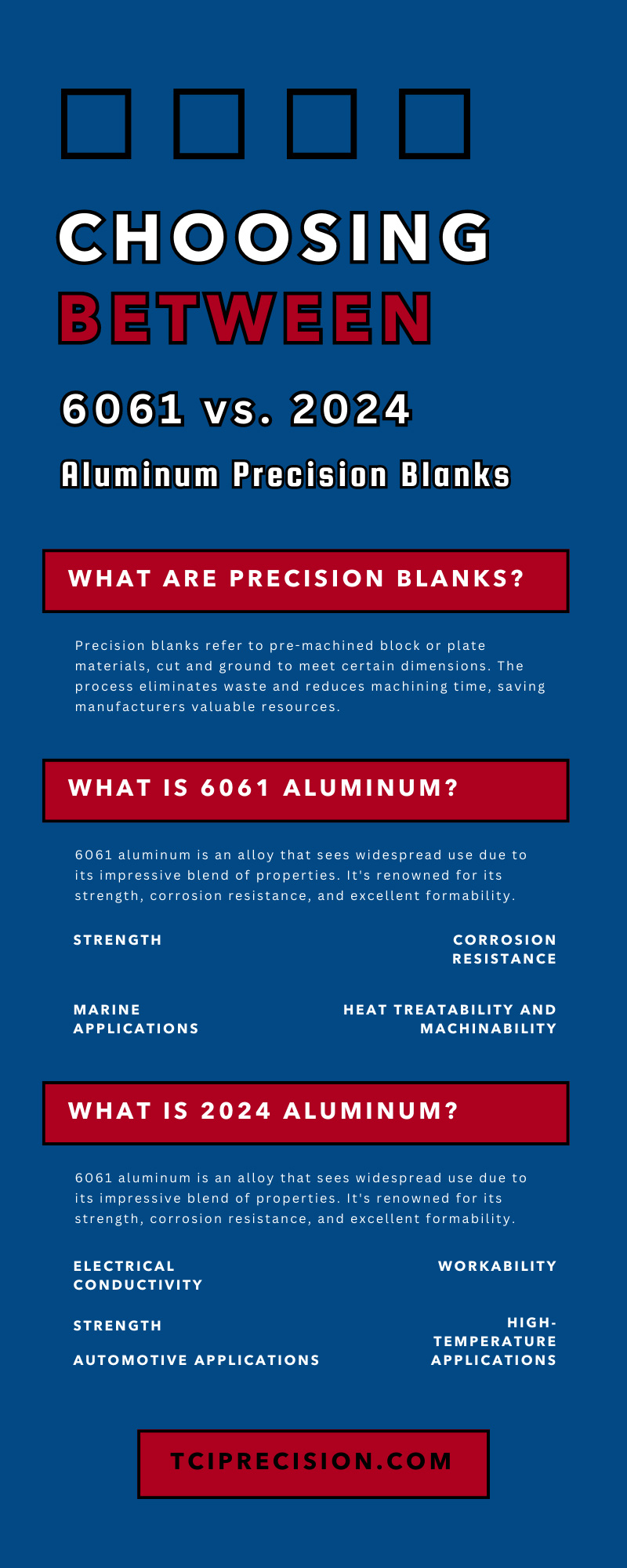

What Are Precision Blanks?

Precision blanks refer to pre-machined block or plate materials, cut and ground to meet certain dimensions. The process eliminates waste and reduces machining time, saving manufacturers valuable resources. Precision blanks are often favored in high-volume production jobs, where accuracy and consistency are of paramount importance. Understanding the distinctions between various materials used for precision blanks is key to selecting the perfect fit for a given job.

How Are Blanks Made?

Creating precision blanks is a multi-step process that requires meticulous attention to detail. The journey begins with the selection of the appropriate raw material, which is then cut into rough, oversized parts. These parts are subsequently milled and ground down to precise dimensions, eliminating any variance or discrepancies. The edges are deburred to ensure a smooth finish, resulting in a precisely sized blank that’s ready for further machining or fabrication.

6061 Blanks

First, let’s take a look at 6061 aluminum blanks.

What Is 6061 Aluminum?

6061 aluminum is an alloy that sees widespread use due to its impressive blend of properties. It's renowned for its strength, corrosion resistance, and excellent formability. As a heat-treatable aluminum alloy, it provides manufacturers with the flexibility to strike a balance between hardness and malleability, making it a versatile choice for a variety of applications.

Corrosion Resistance

A standout attribute of 6061 aluminum is its resistance to corrosion. This trait makes it particularly well-suited for applications in environments where exposure to moisture and corrosive elements is a concern. The strong oxidation layer it forms when exposed to air further enhances its ability to withstand rusting and degradation over time.

Strength

Although it's categorized as a medium-strength alloy, the strength of 6061 aluminum can be significantly enhanced through heat treatment. This attribute, along with its good formability, offers manufacturers a degree of flexibility when it comes to balancing strength requirements with ease of fabrication.

Affordability

One of the reasons behind the widespread use of 6061 aluminum is its affordability. This alloy provides an excellent cost-to-performance ratio, making it an economical choice for manufacturers who need a material that delivers reliable performance without breaking the bank.

Marine Applications

The excellent corrosion resistance of 6061 aluminum, coupled with its good strength-to-weight ratio, makes it a fitting choice for marine applications. It can withstand the corrosive effects of saltwater, making it ideal for building components of boats and other marine equipment.

Heat Treatability and Machinability

6061 aluminum is highly responsive to heat treatment, allowing manufacturers to manipulate its properties to meet specific requirements. Moreover, its machinability is superb. It can be easily cut, milled, or turned, which makes it a popular choice for a variety of applications.

Disadvantages

While 6061 aluminum has numerous advantages, it's not without its drawbacks. Its welding characteristics, for instance, can be challenging to work with. On top of that, while it offers good strength, it may not be suitable for applications that demand the highest level of structural durability.

2024 Blanks

Now that you know a bit about 6061 aluminum, let’s discuss another fantastic option: 2024 aluminum blanks.

What Is 2024 Aluminum?

2024 aluminum is another popular alloy, well-known for its high strength and excellent fatigue resistance. Unlike 6061, however, it isn't as easily machinable or weldable, making it less versatile but more specialized for certain high-stress applications.

Electrical Conductivity

A substantial advantage of 2024 aluminum is its solid electrical conductivity. This property becomes crucial in industries that require the efficient transmission of electricity. Electronic devices and electrical wiring, for instance, can significantly benefit from this particular characteristic. While it may not match the electrical conductivity of copper, it's still quite efficient, especially when you factor in its lighter weight.

Workability

2024 aluminum's workability is somewhat limited when compared to 6061. It's not as formable and is often not the first choice for applications requiring complex shapes or extensive forming. However, its superior strength makes it suitable for applications where these limitations are not a concern.

Strength

One area where 2024 aluminum truly shines is its strength. This alloy is significantly stronger than 6061, making it an ideal choice for high-stress applications. It's particularly favored in the aerospace industry, where its high strength-to-weight ratio is highly valuable.

High-Temperature Applications

Unlike some materials that lose their strength under increased temperatures, 2024 aluminum's strength can increase when subjected to elevated temperatures. This trait makes it an excellent choice in sectors such as aerospace, where materials must endure intense temperature fluctuations without failing. The resilience of 2024 aluminum under heat contributes to its reliability and longevity, reducing maintenance costs and enhancing safety in the creation of various items, from aircraft parts to spacecraft components.

Automotive Applications

Given its high strength and fatigue resistance, 2024 aluminum is often chosen for automotive applications. This sector demands materials that can withstand extreme stress and harsh environments, and these ready-to-ship aluminum blanks fit the bill perfectly.

Disadvantages

However, 2024 aluminum does have its shortcomings. It lacks the corrosion resistance of 6061, requiring a protective coating for many applications. It's also more challenging to work with due to its limited formability and machinability.

6061 vs. 2024: Key Differences

Ultimately, the choice between 6061 and 2024 aluminum precision blanks hinges on the specific needs of your project. If you prioritize formability, corrosion resistance, and affordability, 6061 might be the way to go. On the other hand, if your project demands a high-strength material capable of withstanding intense stress, 2024 could be the better fit. Understanding these key differences can help you make an informed choice and ensure the success of your manufacturing endeavors.

Now that you know how to choose between 6061 and 2024 aluminum precision blanks, you're equipped to make an informed decision for your specific needs. Both alloys have their unique strengths. 6061 offers excellent corrosion resistance and is an affordable, versatile choice, while 2024 provides superior strength and high-temperature resilience, making it ideal for demanding industries like aerospace.

Your selection ultimately depends on your project requirements, budget, and industry standards. Always remember that precision matters in manufacturing, and a suitable choice of materials can significantly impact the success and efficiency of your project.