- Home

- Browse Catalog and Order Now

- Ready to Ship Blanks

- Made to Order Blanks

- Aluminum & Steel Custom Vice Jaws

- Metal Services

- Materials

- Company

- News

- Contact Us

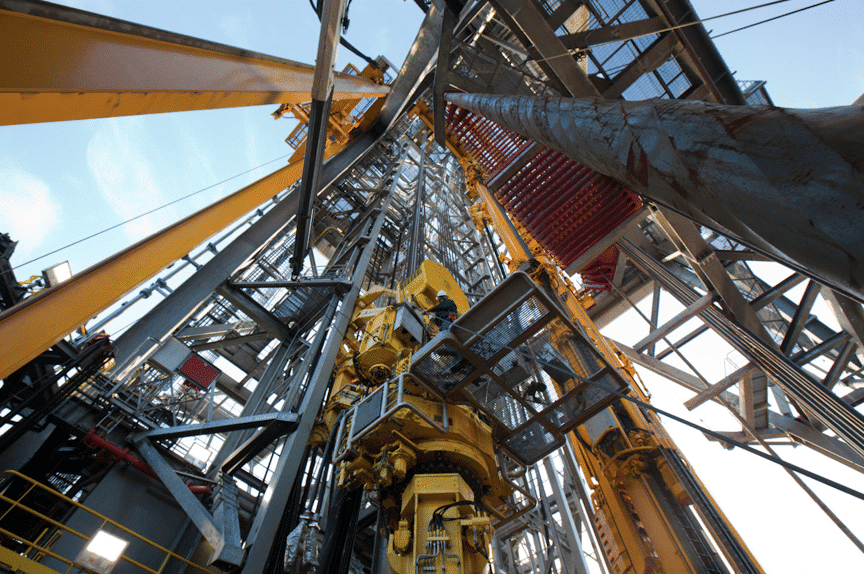

Machining for the needs of today’s oil and gas industry can be complex and challenging. Parts must be designed and manufactured to stand up to abusive conditions and the range of available materials must be extensive. When oil and gas is flowing, time is money. TCI Precision Metals combines our vast access to on hand material inventory along with the range of services necessary to complete critical jobs to spec and on time. TCI provides Custom Machine-Ready Blanks, Standard Blanks, Dovetail Blanks, Feature-Added Blanks, specialized grinding, milling and other machining services to help you manufacture quality. Our Additional Services enable us to provide a wide range of expanded services such as tapping, deburring, drilling, internal threading and hog outs. We also offer secondary services, such as plating, anodizing, heat treating, and welding.

Some of the materials we work with on oil and gas jobs include:

ISO 9001:2008 certification reflects our commitment to quality, on time delivery and continuous improvement.