Part Movement During Final Machining Can be Frustrating - TCI Precision Metals Can Help!

As most shops know, battling residual stress while trying to nail down tight machining tolerances can be very frustrating. Many metals, and especially aluminum and stainless alloys, have residual stress that can cause material to move during machining. Sometimes material bows, sometimes it “potato chips”, sometimes it seems like it’s “alive” and totally unpredictable - and it’s a relief when it stays put. The potential for this problem increases with light gauge plate and sheet. And as the thickness decreases and the width and length increase, the problem is compounded. With this kind of ratio of thickness to width and length, there is a greater tendency for movement and workholding is more challenging. Even with well-designed clamping, you’re often not out of the woods; a finish machined part can look great until you release a part from the restrained condition, and then the part moves.

Residual stress is typically introduced into material during the rolling process at the mill (domestic or foreign). When an aluminum ingot is rolled to its final thickness, it’s subjected to high pressure and heat. This can create areas of stress throughout the material that are hard to identify and even harder to eliminate even after stress relieving by stretching. Many mill and distributor reps will tell you, “that’s just the way it is; deal with it”. Well, that may be so in some cases, but there are also some straight-forward solutions that can minimize or even eliminate part movement. At TCI, we have been experts at this for over 60 years in the production of Machine-Ready Blanks.

First, it always helps to order material with the grain direction with the length of the part. Sometimes it could be a wee bit more costly on the front end. But during the machining ops, a shop will make up that difference, and more, in no time even if the part has not been milled or ground to size prior to machining.

Second, it’s important to know that machining the face of a part one-side-at-a-time will typically, and very quickly, make matters worse. Removing stock from one side at a time will usually cause a part to bow. Then comes the frustrating part of flipping the part over to do exactly the same thing to the other side. It may bring the part into a flat condition but usually not without another machining op or flattening.

Also, machining large amounts of material from one side of a part (pocketing) will almost always introduce stress and part movement. TCI can remove that material through rough machining, relieving the inherent stress, and then duplex mill and/or double-disc grind to final Machine-Ready Blank specifications. Bingo…flat part.

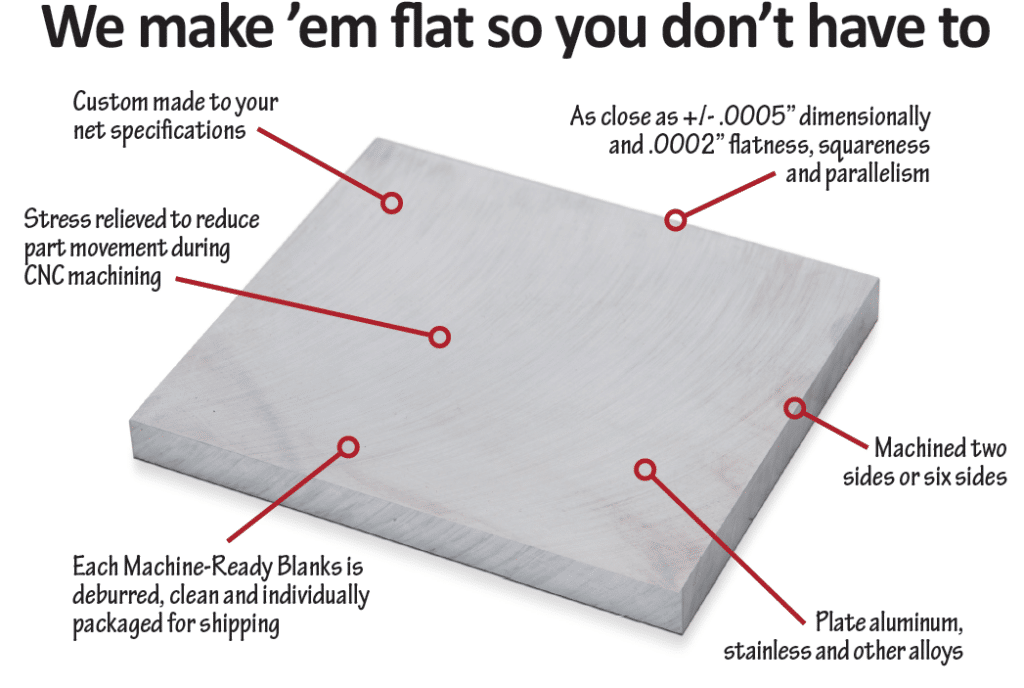

Now, I tell you all that to tell you this: The best and most cost-effective solution for the material movement issue is to bring in Machine-Ready Blanks, from TCI of course (the shameless plug), ready to finish machine. The process of machining and/or grinding of both sides of a part at the same time reduces residual stress while providing better flatness and parallelism. At TCI, we learned decades ago that parts that have been duplex milled and/or double-disc ground prior to final machining, get machined much quicker on our customers’ floors.

First, one operation is eliminated; the necessary one of bringing a part to size. Yes, it can be done as part of the finish machining operation, but there are material movement risks involved. Why not just eliminate that risk up front?

Second, since an operation is eliminated and you can go right to final machining, shop throughput is increased. That means less time spent wrestling with part qualifying and part movement and more focus on getting the part out the door to the downstream manufacturer, the eventual customer.

Third, remember that ordering a Machine-Ready Blank ahead of time means that you can have parts that arrive to your net tolerances – and most of the time much closer than that. An added benefit is that your parts will also be consistent in size and flatness, saving valuable time in program offsets and set up.

In production machining, there is no ‘one size fits all’ strategy to reducing material stress and the associated part movement during final machining. But good, productive conversations with our experienced crew regarding best practices in ordering and methods engineering on your shop floor could well save you a lot of frustration with material that feels alive and help you to get parts out your door quicker. I think that means better productivity and profit for you, right?

Thanks for reading -

John